There’s one page is related with supply chain: Link

No designated page for supply chain, but here are what related:

Industries section -> Travel, Logistics & Infrastructure

Capabilities section -> Operation

McKinsey’s selling points

To me, it covers three main perspectvies: 1. Build a more stuctural way to deliver outcome; 2. Digital transformation and optimizaion; 3.Empower.

- Use supply chain and manufacturing operations to create winning strategies: An interdisciplinary approach—drawing insights from commercial, marketing, IT and digital, and product design—helps clients to unlock next-level productivity gains.

- Take a holistic approach to transformation to capture end-to-end value: An interdisciplinary approach—drawing insights from commercial, marketing, IT and digital, and product design—helps clients to unlock next-level productivity gains.

- Transform manufacturing processes for better productivity: Encompass everything from digital diagnostics to plant transformations, order management, asset productivity, predictive maintenance, resource-production manufacturing, and lean warehousing.

- Boost operational health by identifying skill gaps and building capabilities: Partner with clients to build foundational enablers and develop skills through capability building to create rapid and sustained impact.

- Foster a quality culture to create competitive advantage: Help to meet and exceed customer expectations at every touchpoint through benchmarking, developing quality and compliance strategies, and remediation services across the entire value chain and product life cycle.

-

Leverage digital and autonomous supply chain opportunities: Supply chain 4.0 by incorporating IoT, robotics, and analytics. Removal of silos across the supply chain, resulting in lower costs, smaller inventories, and fewer lost sales.

The page of the link also includes some informative articles created by McKinsey, below are something I found useful:

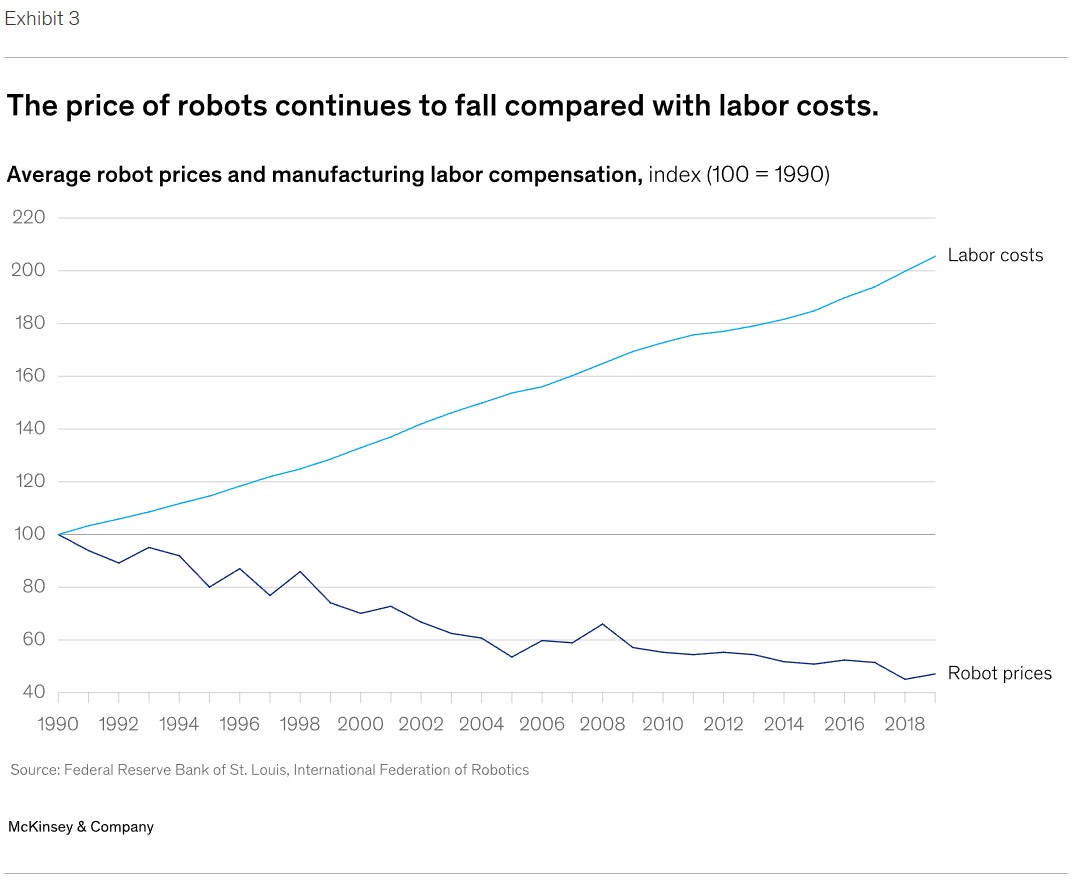

Summary: 2 Reasons for automation: insufficient laber supply and increasing wages. 2 Benefits: Reduce the number of low-skill roles (which is the hardest to find) and change the nature of workplace to a more technical one.

Cost decreased bt more than 50% over past 30 years:

2. Adopting AI at speed and scale: The 4IR push to stay competitive

Summary: Interestingly indentified AI as 4IR (the forth industrial revolution)

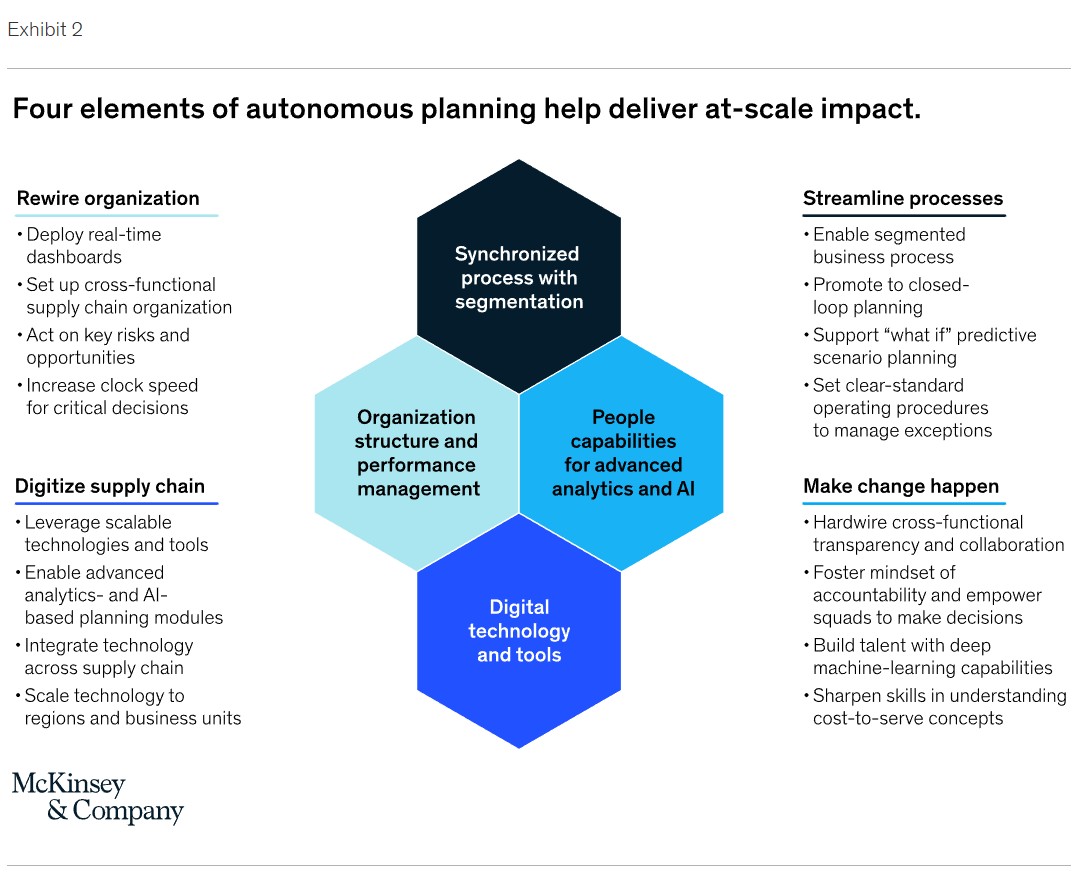

3. Autonomous supply chain planning for consumer goods companies

Summary: Autonomous supply chain planning can lead to: 4% UP revenue of up to 4 percent, a 20% decrease in inventory, and a 20% decrease in supply chain costs.

Four elements to deploy autonomous planning